Product

IBC - Containers

Intermediate Bulk Container with safety, economy, and environment protection. Modern warehousing, transportation of liquid products the necessary tools.

One tons square barrel is initially based on the use of four drums space realization of shipment force of five drums and design, packaging liquid cargo is the most economical. Packaging can be repeatedly used, no external impact case life up to 10 years, this package designed specifically for container transport dimensions, especially suitable for a variety of container transport. To install a 20-foot container exports, for example, such as the use of our plant containers, drums and more shaped than carrying about 4 tons of raw materials.

IBC TANK inner and outer layer of a fluorinated, liner using a high density polyethylene is also excellent mechanical properties, including tensile strength, elongation, hardness, and thermal cracking grip performance, low temperature performance is not affected by SMP treatment effects, widely suitable ⅱ and Ⅲ category of dangerous chemicals packaging, transport and storage. And the IBC TANK has a very low penetration rate for the environmental benefits provided, the barrel can be up to 20 years without weathering, and the various components can be achieved in the use of recycling, which are making it more environmentally friendly, a new generation of liquid packaging containers. Many types of IBC TANK selection, greatly increasing the degree of personality loaded barrels to meet customers' changing requirements. We offer a low price refurbished, the same quality assurance, with a new barrel standard IBC container barrel. IBC container barrel has become all kinds of chemical, food, pharmaceutical, oil, chemicals and other liquid packaging.

Instructions for use

1. IBC TANK metal frame by the content and the combination of content uses high molecular weight high density polyethylene blow molding, high strength, corrosion resistance, and good health. External metal frame adds to safety and reliable.

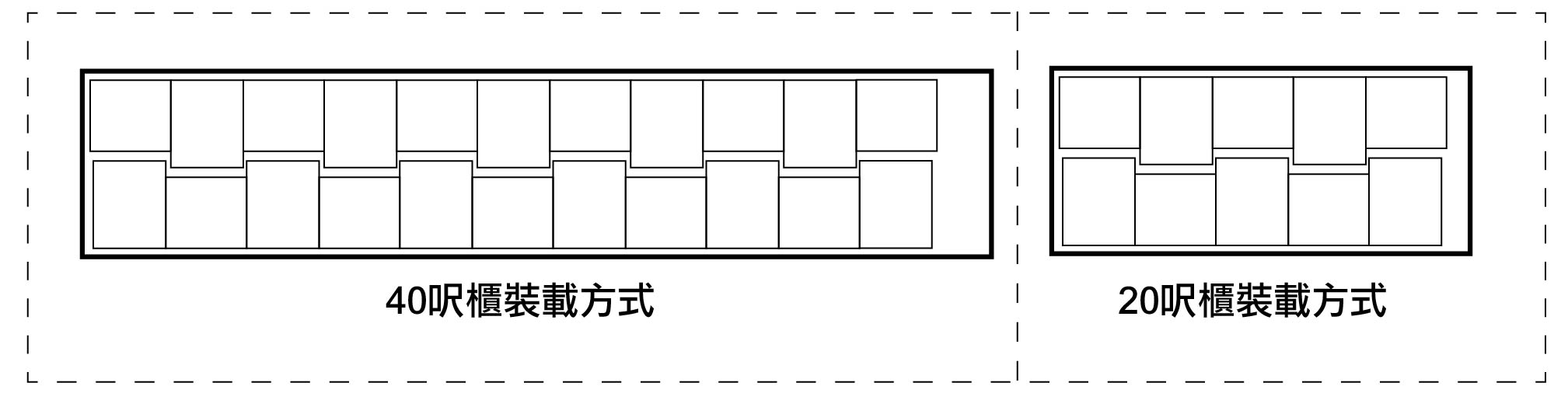

2. Dimensions comply with ISO container design standards, perfectly suited to road, rail, sea and air transport. Especially for maritime container transport. 40 feet container can hold 42/20 feet container can hold 18 to 20

1. Can significantly reduce the production, storage, transport, handling costs. Save a lot of manpower and material resources. The smallest footprint for maximum packing capacity, space utilization will be increased by 25% or more (1000 liters container barrels, compared with 200 liters plastic pail)

2. During storage space can be used, laminate stacking, can be stacked up to four layers, greatly reducing storage and transportation costs.

3. Loading and unloading operations can be used forklifts, reducing the manual handling of a lot of trouble. Filling 1 IBC TANK = 5 200L barrels, the filling process reduces the hassle of repeated operations, while avoiding the filling process material leakage, spills and other waste.

4. Container with a discharge valve, you can use the weight of the liquid natural drainage, no further increase in the power plant, drain thoroughly, quickly and safely.

.jpg)

【Environmental protection】Easy to clean design, can be reused many times, packaging cost savings and environmental protection.

(1)The outer frame and tray products using heat treatment, galvanizing technology. Frame, light weight, good toughness, high load capacity and withstand external shocks, the largest irrigation products like density of 1.9, is particularly suitable for re-use within the enterprise and product packaging for export.

(2)Pressed from sheet tray, designed with a tilt bottom, drain thoroughly, leaving no residue, easy to clean.

(3)The use of advanced molding technology to ensure the content is of uniform thickness without distortion, high precision molding and long service life.

(4)Production process applied mechanization, automation and computer numerical control and other high technology, it is the product of the technical parameters, weight, and quality is stable and reliable.

(5)IBC container barrel factory is particularly suitable for general cargo loading liquid outlet, customers can greatly reduce the cost of production.

(6)Stored procedures can use space, laminate stacking, can be stacked up to four layers, greatly reducing storage and transportation costs.

(7)Loading and unloading operations can be used forklifts, reducing the manual handling of a lot of trouble. Filling 1 IBC TANK = 5 200L barrels, the filling process reduces the hassle of repeated operations, while avoiding the filling process material leakage, spills and other waste.

(8)With a discharge valve, you can use liquid weight, natural drainage, without over another power plant, drain thoroughly, quickly and safely.